- Home

- News & Newsletter

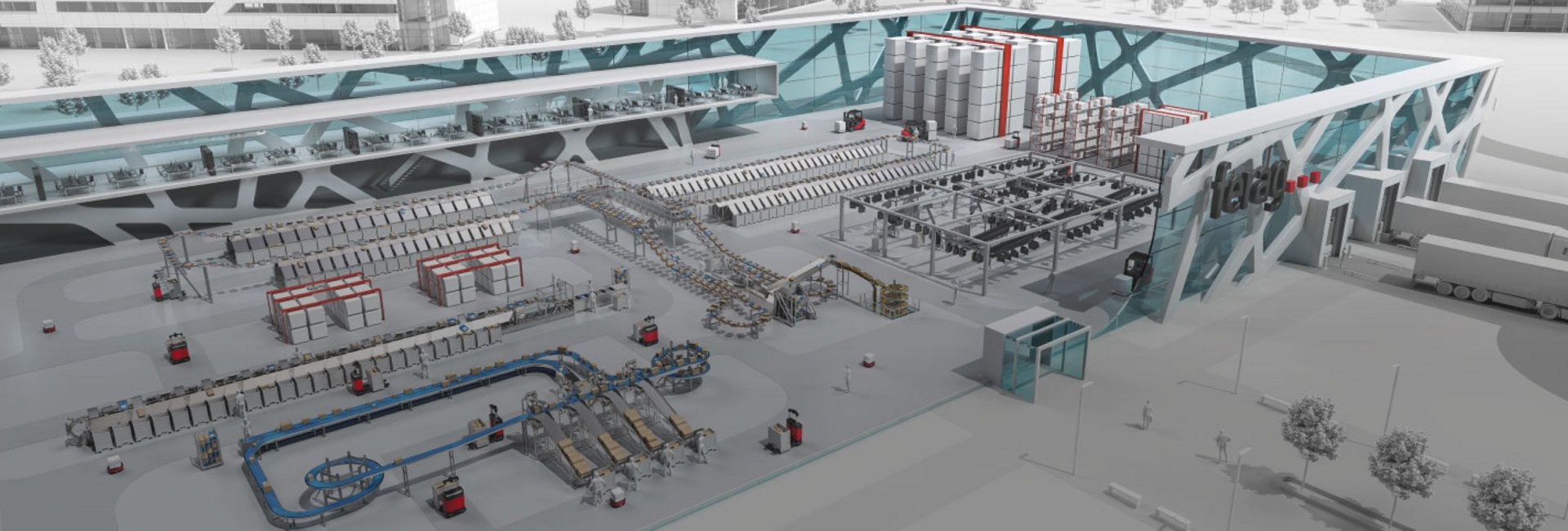

- Ferag sorting systems increasingly prevalent in distribution logistics

Ferag sorting systems increasingly prevalent in distribution logistics

The sorting and conveyor technology from Ferag is the result of the further development of finishing lines originally conceived for print media production, with the company bringing over 60 years of experience as technology leader to the table here. Despite their different design and functions, material flow systems such as Denisort, Deniway or Skyfall all have something in common. All technologies – whether a compact tray sorter, 3D plate chain conveyor or pouch sorter – have a high degree of modularity. The modular system ensures that the systems provided by Ferag for use in distribution logistics can be scaled without problems and adjusted to changing needs over time with very little effort. This aspect has proven a major plus point time and again, above all in fast-paced branches such as fashion or rapidly expanding segments such as e-commerce. At the same time, the systems from the Swiss materials handling specialist also impress thanks to their high energy efficiency. On the Skyfall overhead conveyor, for example, longer straight sections can be designed in such a way that the individual carriers move by gravity only. The closely related Denisort, Deniway and Easychain systems also require very few drive elements, which not only leads to energy savings but also a significant reduction in maintenance and running costs.

Buffering and sorting with a high degree of automation

Order fulfilment for clothing and fashion products has become one of the main domains of the Skyfall overhead conveyor. The system can be used both for folded goods and garments on hangers (GOH). Its success is based on high throughputs and extensive automation. Among other examples, MAYORAL from Spain – the European market leader for children’s fashion – was able to speed up its distribution processes significantly thanks to a huge Skyfall system, with 12,000 units per hour now being handled. What’s special is that the lines can not only be automatically loaded and unloaded, they can also process a wide variety of goods in hanging pockets and on hangers uniformly and smoothly. With over 67,500 shuttle hangers for GOH, a primary buffer for 60,000 items and a matrix sorter for 6000 items per hour, the Skyfall system recently put into operation at PEERLESS CLOTHING in the USA also sets new benchmarks in fashion logistics.

Conveying and sorting in one end-to-end system

The Denisort tilting tray sorter has quickly built up a good reputation as an absolutely reliable sorter for different goods types and packaging sizes – both for classic shipping boxes and polybags. Depending on the application, the highly flexible tray system with trays that tilt to either side can achieve a throughput of up to 12,000 units per hour – and all with an almost unlimited number of sorting destinations. This depends solely on the space available for the unloading points and chutes. Projects involving the sorting and allocation of shoes (MYBOX), spectacle lenses (ZEISS) or photo albums (CEWE) demonstrate how well the Ferag engineers have fine-tuned Denisort for the gentle handling of products. Furthermore, they have also developed solutions specially for the e-commerce segment in order to link the Denisort lines used here for outbound sorting seamlessly to upstream and downstream areas via AGV. A concept of this type is currently being implemented at ZALANDO in Erfurt, with several Ferag systems already in operation here in addition to Denisort and Deniway systems. The latter of these systems is used by the online mail order company for the disposal of used cardboard boxes, among other applications.

Optimal solution for sorting in second packaging

The proven conveyor systems Deniway (up to 50 kg of weight per linear metre) and Easychain (up to 20 kg of weight per linear metre with tighter curve radii) are unbeatable in one respect: they form the most efficient interface between upstream production and palletizers currently available on the market. This is why they are used predominantly in the manufacturing and distribution of food and beverage (NESTLE, GENNARI, FORNO BONNOMI, BISLERI). Another application can be found in the seamless flow of materials for healthcare products (ASTRA ZENECA, BEIERSDORF) between first and second packaging, where quality, reliability and ease of maintenance are of the utmost importance in addition to gentle handling. It goes without saying that the Ferag systems can also be combined with one another. For example, the combination of Denisort line and Deniway loop allows for optimal order fulfilment at Finnish book wholesaler KIRJAVÄLITYS.